The Benefits of Mixing Properly

Why You Shouldn't Use an Ordinary Drill for Mixing Concrete, Grout, or Mortar

Every job has a specific tool that best suits the needs of the task. Pairing the right tools with the job on a construction site will reduce wasted time and money. Mixing construction material, such as cement or epoxy, is one of those tasks that requires using tools optimized for the process. While a drill may be a commonly used tool for mixing on construction sites, it is one of the least effective, especially for heavier substances. Would a concrete mixing drill or mortar drill mixer be more suitable for the job for example? The question should not be, can you mix cement with a drill, but should you? Better solutions exist for more even and powerful mixing of all materials from thin to thick.

Why Drills Don’t Work for Mixing on Construction Sites

Mixing paddles should not be powered by electric drills for many types of mixtures. Drill motors lack the necessary power for moving a mixing attachment through heavy materials, have gearing optimized for speed over torque, can overheat, increase the chances of worker injuries, and produce potentially inconsistent results. There are, however, proper drill attachments for mixing concrete.

Power. The design of drill motors optimizes speed over power to reduce the time needed for drilling holes. Less power and higher speeds work well when creating holes or inserting screws. These attributes don’t work when using a large mixing paddle or a drill to mix concrete.

Drill motors typically lack the ability to turn a drill mixer attachment through heavy materials. Paddles require powerful motors to turn, especially for extended mixing times. Drill motors used for small batch mixing often overheat due to their inability to handle the extra force of turning a paddle. Nor do they work well for long mixing times.

Speed. Drills have small motors that allow for handheld use when drilling into various materials. Their relatively tiny gearboxes don’t efficiently transform the bit speed into torque. When using a mixing drill bit, or drill attachment for mixing concrete, the small gears cannot generate the turning power needed to move the attachment through heavy or viscous substances. In some instances, drill motors may work briefly for mixing lightweight liquids in very small amounts. But in the case of a cement mixing drill, for example, they cannot perform as needed for mixing large volumes or dense materials.

Overheating. The importance of pairing a tool with enough power to do a given job can extend its life. Motor strain leads to overheating of the power tool and premature wear and tear. Either smoke or a hot exterior on a drill during mixing indicates a serious problem with the motor being overworked. Continuing to use the drill will turn it into a useless brick, wasting time and money on the job site.

Ergonomics. Bending over a bucket to use a handheld electric mixing drill for mixing puts a strain on the back and arms of the operator. Repeated strain of this type increases the chances of muscular-skeletal disorders (MSD). This injury category includes chronic problems, such as arthritis, and acute issues, such as muscle strains and accounts for time off work and reduced productivity for workers.

Across all industries, MSDs account for the greatest percentage of new work-related conditions. Research shows that while the general working population reports an incidence rate of 33% for MSDs, the construction industry, has a much higher proportion, 77%. MSDs may lead to setbacks in construction schedules and extra costs in worker compensation.

Inconsistent Results. Drills experience excessive strain when mixing materials. On the construction site, the lack of power from a drill motor can produce inconsistently mixed materials, especially when using the same drill to mix multiple batches. Wear on the drill’s motor may result in the later batches not having enough power to evenly distribute the ingredients.

Thorough mixing is important for the chemical reactions among ingredients to occur. Not mixing long enough or using a drill that mixes too slowly could prevent the solids and liquids from evenly distributing. Therefore, the full reactions cannot take place. Products made with poorly mixed epoxy, mortar, or concrete, may not perform as expected. When thinking about the proper drill to mix concrete, a mortar drill mixer, cement mixing drill, or concrete mixing drill are all the types of tools that are needed to prevent some of these problems.

To solve the above problems inherent in using electric handheld drills for mixing, we created the Collomixer.

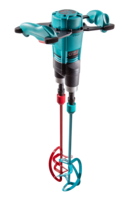

Collomixer Drill Mixers and Paddles are Solutions for On-Site Mixing

Mortar drill mixers and cement mixing drills need optimum power to rotate their large mixing paddles through heavy or dense material. Drill motors do not have the optimum power to turn larger mixing paddles through heavy or dense materials. The Collomixer line overcomes these issues through greater power, a range of accessories to speed up the mixing process, the quick-change HEXAFIX to switch paddles without additional tools, and better ergonomic designs.

Power is the key for mixing small batches ranging from one to four bags of material on-site. Drill motors lack power for attaining the speeds necessary for turning the mixing drill bit or drill attachment through viscous or heavy materials..

While drills only suffice for mixing thin liquids in small amounts, larger volumes or heavier weights need more power behind the mixing paddle. The Collomixer line includes products with more powerful motors designed for thorough combination of all mixture types.

Collomixer products present solutions for all the problems of using drills for mixing heavy materials. Even the smallest Collomixer option used for batches up to 10 gallons, the Xo 1R, has a powerful 1.4 horsepower motor. The most powerful mixer, the single-spindle Xo 6R features 2.1 horsepower and can handle up to 24 gallons at a time. To mix the heaviest materials, the Xo 55R Duo uses a pair of counter-rotating spindles to move through the thickest mixtures.

Speed control is equally as important as power for mixing a wide range of materials. Both the Xo 4R and the Xo 6R include dual-speed motors to adjust the mixing speed based on the material used. When coupled with the appropriate paddles, like a drill attachment to mix concrete, these mixers can tackle almost any job site mixture from paints to grout.

HEXAFIX. Our mixing paddles include options with either HEXAFIX or standard shaft ends. Collomixer products use the HEXAFIX for the toolless connection of the paddles to their bases. Standard shaft ends fit into drills for mixing small volumes of very thin liquids.

The HEXAFIX fitting allows for the fastest possible switching of paddles. They decrease the time needed to switch paddles, reducing the overall time spent mixing on the job site.

Ergonomic design can prevent repetitive strain injuries. Reducing the amount of bending down or the time spent using vibrating tools can lower the incidence of muscle strain.

Collomixer products do not require bending over to hold a concrete mixing drill, in turn protecting backs from wear and tear. They also have a more ergonomically friendly design that minimizes muscle strain and fatigue during operation.

Drills require bending over and supporting the vibrating tool in an uncomfortable position while mixing. For short mixing times of thin products, these don't pose too many problems for operators. But longer mixing times raise the chances of muscle strains and fatigue.

Less time spent using a tool is another unexpected aspect of ergonomic design. Drills don’t have the power to mix materials as quickly and thoroughly as needed, therefore requiring extra time when handling these power tools. Collomixer products have extra power to properly mix all different types of material consistencies quickly. When paired with the correct paddle attachment, the Collomixer reduces mixing times for most materials compared to underpowered electric drills. It is the right choice of drill to mix concrete and other materials.

Choose the Right Paddles to Match Your Materials and Mixing Needs

The paddles used for mixing have an equally significant role as the motor used. All Collomix paddles come from the same high-quality manufacturing process that uses durable, high-grade steel. Strongly welded joints ensure the paddles can withstand heavy-duty use, particularly those drill attachments for mixing concrete.

For the best results when mixing, select a paddle suited to the task. When choosing the right paddle for a job, the viscosity of material, type of material, and mixing methods all matter.

Material viscosity is the most important criterion when finding a paddle that will perform optimally. Mixtures fall into three main categories with numerous materials within each group. liquid, creamy and compact. They each require specially designed paddles for the most effective mixing.

The LX paddle mixes liquid materials, such as wall paints, top coatings, sealants, and epoxy coatings. Another liquid mixing attachment is the FM paddle for primers, glazes, and liquid waterproofing systems.

Runny mixtures, such as thin-bed mortars or leveling materials, mix best with a mortar drill mixer attachment like the DLX paddle. The KR paddle best combines runny tile adhesives, fillers, and adhesive mortars.

Compact materials require the toughest paddles to move through the dense mixtures. Cement mixing drills and concrete mixing drills feature the MK paddles which combine all types of mortars and concrete. WK paddles power through cement plaster and grouting mortar.

The type of materials mixed will also affect paddle selection. Unexpected results often happen when using the wrong paddle.

Clumps may form when mixing powdery solids with liquid if not using a paddle that appropriately breaks up the solid and evenly distributes it through the liquid.

Reaction resin mixtures that harden quickly may require premixing separately or using a dual-spindle paddle to achieve faster mixing that reduces premature hardening.

Pairing the correct paddle with the types of materials being combined ensures successful mixing.

Mixing actions also contribute to paddle selection. Paddle design determines the flow of materials through the blades.

Heavy materials, such as concrete, mortar, screed, or plaster require the ingredients to be moved upward through the container to mix. An appropriate concrete mixing drill for this job uses paddle designs WK and MK to push the mixture from the bottom to the top to ensure a thorough combination of the components.

Mixing from the top to the bottom reduces the splashing of low-viscosity or soft materials. DLX paddles force the top of the mixture downward through the blades for even mixing.

Not all paddles have parts that direct the mixture vertically. A proper mortar drill mixer uses horizontal mixing with a KR paddle and homogenizes mixtures that require even consistency, such as tile adhesives or adhesive mortars.

The heaviest mixtures, including concrete, may require the additional force of a pair of paddles that use forced mixing action. The best drill attachment for mixing concrete uses a counter rotation of the two spindles in the MKD paddle. This concrete mixing drill eases the strain on the operator by the torques of the spindles canceling each other out. This action also intensely mixes all materials for fast, even combining of ingredients.