How to mix really well!

Tips for Flawless Mixing

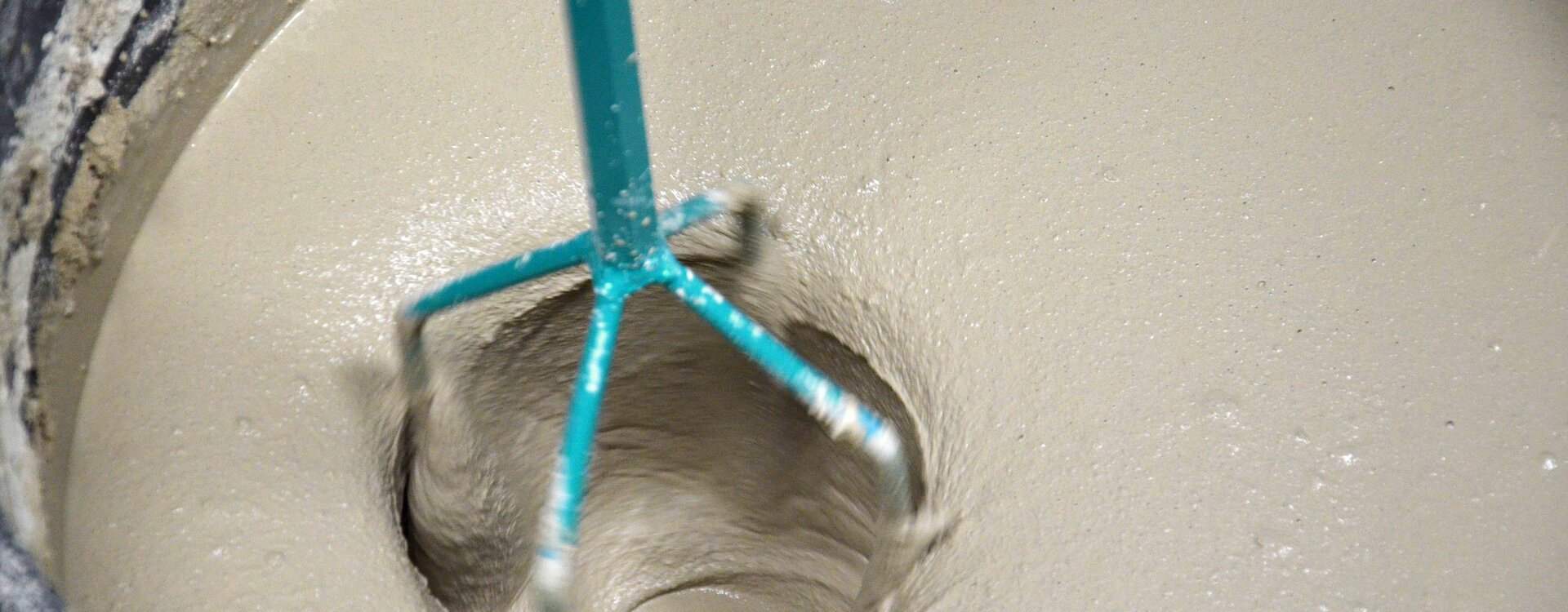

For quality-conscious craftsmen, producing the perfect mixture of building materials, such as tile adhesive, screed or leveling compounds, is not a boring side issue. You know how important the perfect homogenization of materials is for the rest of your work. Lumps in the floor compound, dry, unmixed material residue in the bucket or sticky surfaces after the application of synthetic resins are all familiar issues faced during everyday work.

As experts in the field of mixing, we focus exclusively on the successful preparation of material and would like to offer you some tips for better mixing and problem-free working below:

#1 – The right shape of mixing paddle

You wouldn’t use a wood drill bit to drill into a concrete ceiling, would you? This makes sense to most people, but when it comes to mixing, they often only use one type of paddle. Just looking at the wide variety of chemical construction materials makes this misconception clear. The content of the bags with material usually looks the same: it’s all grey powder. But as soon as it is mixed with water, the powder either converts into a thin self-levelling compound, a soft plastic adhesive mortar or a stiff mortar filled with sand.

It’s becoming increasingly obvious that this process requires the most effective paddle possible. If the design of the paddle does not match the properties of the mix, the results will be flawed. The material cannot be broken down properly or you cannot reach the bucket base due to the incorrect mixing effect. Additionally, hand-operated mixing with a stirrer is physically very strenuous and time-consuming.

Another important factor to consider is the diameter of the paddle. It should always be adjusted to the amount being mixed. If it is too small, it will take much longer and the effect will be too weak. If it is too wide, the material may be ejected out of the bucket, dirtying the user and the surrounding area.

You can find out which mixer is the right one for which material and quantity here.

Whether grainy and heavy, creamy and plasticky or flowy - the right paddle ensures the best results.

#2 – Choose a suitable size of mixing bucket

Which bucket is suitable for which material depends primarily on the quantity of material being mixed.

Everyone agrees on one thing: if the bucket is too small, it will not only affect your work pants, which will probably have to be washed, but may also ruin the construction site’s surroundings. Especially indoors, splashes on freshly plastered or painted walls do not look so good.

Ideally, the mixing bucket should be filled up to 2/3 of its height with material. This way, you still have enough room throughout the mixing process and can easily move the mixture within the bucket.

You should also make sure that the paddle is completely immersed in the mixture. This reduces the amount of force required, prevents material from being flung out or excessive air from being introduced into the mixture. You can find out more about suitable buckets here.

#3 – The right motor

Professionals usually use special mixers. This has the advantage that the appropriate amount of power is available for stirring. These power tools transform the force of the motor into torque for mixing. This is why their rotational speed is much lower than that of drills. Drills are only conditionally suited as mixing tools. Since they are usually much too fast, the machine overheats and finally fails within a short period of time, especially when mixing tough or heavy materials.

The rule of thumb therefore applies:

- Heavy masses require a lot of force and therefore a lower speed.

- A faster speed is generally used for thin, light materials.

There are also so-called duo machines. These double mixers with counter-rotating blades are particularly suitable for mixing large quantities of heavy masses, especially quartz-filled epoxy resins. The counter-rotating paddles neutralize the machine’s reverse torque on the operator, which leads to a significant reduction in physical strain. An additional important factor is the large amount of time being saved while mixing. Particularly with heavy mixtures, the total time is reduced by almost half.

More about our hand-mixer program

Mixer-drills and paddles are the solution for professionals

#4 – Observe the correct amount of water and correct sequence

The right paddle, the right hand mixer and the right bucket have been found. Now it's time for the mixing itself. Here, too, are a few factors to consider when trying to achieve a top mixing result. The ingredients of modern construction chemicals are becoming increasingly complex. It is therefore very important to mix the materials correctly.

The key factor here is the right amount of water for the mixture. Follow the manufacturer's instructions, they are there for a reason. Often a little too much or too little water is enough, to make the ratios of the mixture no longer fit. A measuring bucket or a dosing device can be used as an aid. Ready-mixed mortar must not be further diluted with water, otherwise it will "water down" and become unusable.

Basically, the water goes into the bucket first, then the material. If done the other way around, the powder would have to be worked into the water. This is more labor intensive and time-consuming for the person handling the mixer. Mixing errors in the form of lumps are often the consequence. This could later lead to flaking, defects, adhesion problems or leaks. Resulting complaints not only cost the craftsman money, but also reflect poorly on you.

The right amount of water is crucial for a good mixture

#5 – Observe the mixing time

One reason for faulty material is the ignoring of instructed mixing times. Manufacturers specify certain mixing and maturing times for their materials for a good reason. Many products contain chemical additives, which develop their full effect only after a certain period of resting and repeated mixing. Another issue arises from frequent hand-operated mixing: the more frequently materials have to be mixed on a construction site, the more recommended mixing times aren’t followed. Therefore, they get shorter and shorter. So be sure to check your watch. If you are not careful here, problems, frustrations and costs are inevitable later.

The importance of the "maturing time" after mixing tile adhesives or floor levelling compounds is often not clear and therefore ignored. However, it is worth investing these few minutes: during the maturing time, the additives in the fresh mortar can unfold and develop their effect evenly after another brief stirring. The mortar becomes more homogeneous, smoother and keeps its good workability over the specified period.

Perfect material - perfect surface

#6 – Clean Mixing Tools

Be honest: do you clean your paddle after every mixing process? Dried material residue can fall off during the next mixing and contaminate the new material with “foreign bodies”. The individual material layers also gradually build up on the paddle. This causes the paddle to lose significant effectiveness and the mixing times therefore becoming longer. Also, dirty paddles must be replaced more frequently, therefore increasing your expenses. The popular “hammer wash” is not recommended, as it will bend the paddle or tear off welded joints.

The lifespan and effectiveness of the paddle can be prolonged significantly by cleaning it after every mixing process. Cleaning can be very easy. A bucket filled with water and some coarse quartz sand does the job, or, much more elegantly, use theMixer-Clean cleaning bucket.

The easiest way to get clean mixers: MixerClean cleaning system