Double paddle mixer Xo duo

Fast and intensive mixing with double-spindle mixers

Work more easily with hand-operated forced-action mixers

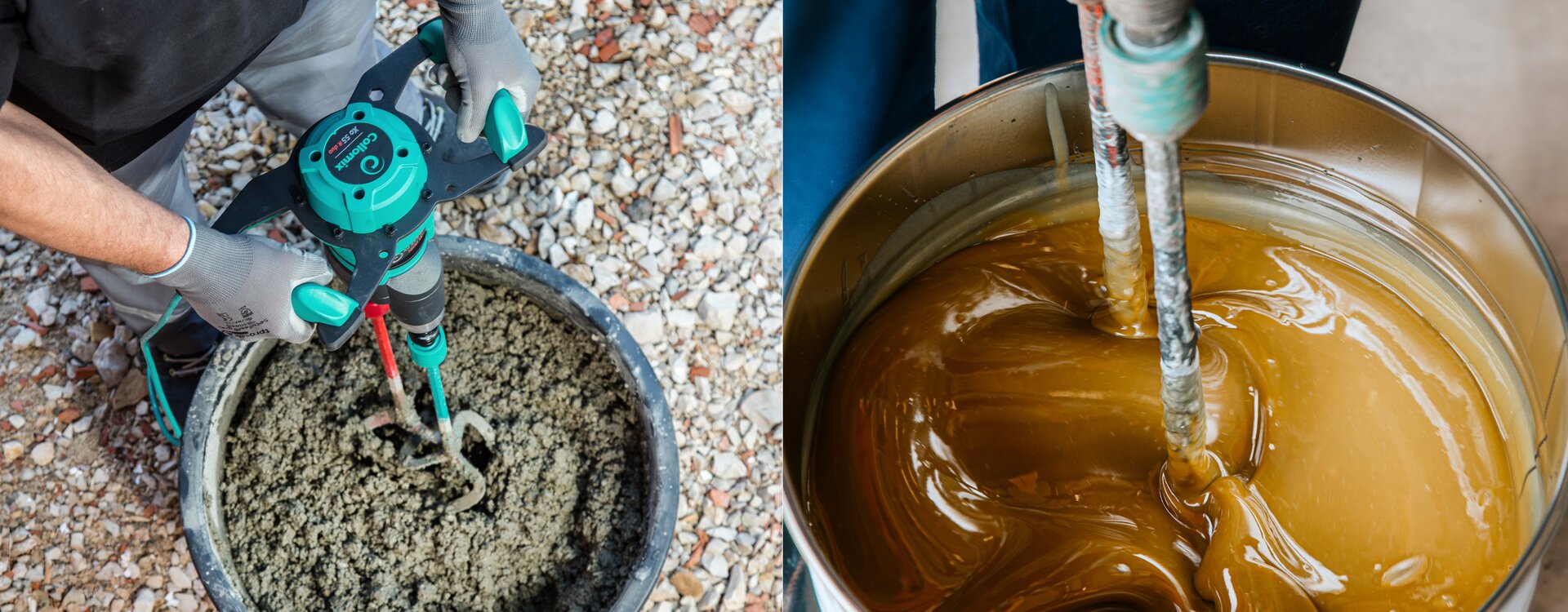

Everywhere, where it depends on fast and intensive mixing of even difficult mixing of tough and plastic materials double-spindle mixers deliver the best results.

Even heavy and dense construction materials are much easier to mix

Multi-component resin based masses are mixed thoroughly in short times

Many of the materials to be mixed are difficult to move during mixing or are particularly tough. Mixing with a single-paddle mixer is therefore more strenuous than usual, both for the operator and the machine drive. This costs energy and fatigues the man at the machine. This can also be a reason why the material is no longer optimally mixed and cannot be processed well afterwards.

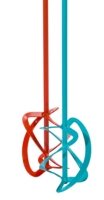

The use of an hand-mixer with two paddles, with the so-called „forced mixing effect“, brings relief. The two paddles rotate against each other and literally pull the material to be mixed towards them. In the mixing zone, the blades of the two agitators work the material intensively and produce thorough mixing of the individual components. This is also much faster than with any other tool.

Another very special advantage is that the counter-rotating paddles mean that the material no longer has a retardation effect on the machine and thus on the operator. Even with heavy, sand- or gravel-filled materials, the machine can be moved in the material with little effort. As standard, the material is also mixed from the bottom up.

This mixing process is also ideal for epoxy and other multi-component resin materials where thorough mixing is essential. With the forced mixing effect, the resin and hardener components are mixed in the shortest possible time and particularly thoroughly, which contributes positively to the improved processability of the materials.

When processing liquid materials, it is possible to interchange the two paddles in the machine and generate a mixing effect from top to bottom. This prevents, for example, material from spraying out of the bucket while mixing.